13 Essential Considerations When Choosing The Right AC Coating System

13 Essential Considerations When Choosing The Right AC Coating System

Consider factors such as pot life, polishing, odour, sheen levels and more when deciding on the correct AC Coating System.

There are a number of AC Coating options available in the market – selecting the best one for your business can be a difficult decision, but there are a few important factors that must be considered.

13 Essential Considerations When Choosing The Right AC Coating System

1. Pot Life

Pot life can significantly vary with some having a short pot life (12 hours), whereas some can provide a pot life of up to 48 hours. (Also be clear regarding the mix ratio when costing - most AC coating products are mixed at a ratio of 10:1, but some at 9:1 or 8-1.

2. Durability

The level of durability is important for the quality of the finish. The majority of AC products will pass BS6250 durability standards, but it would certainly be worth checking the durability standards of the options you are considering.

3. Formaldehyde Content

Almost all AC products contain formaldehyde, which is a carcinogen and therefore has potentially major health threats. Certain products have higher or lower amounts of formaldehyde, so it is advisable to check this.

Readers Also Liked: '4 Things You Must Be Aware Of When Using An AC Coatings System'

4. Yellowing

Due to oxidants contained in the film, AC products will eventually yellow over time. This does effect some more than others due to the type of hardener being used, so be aware of this and choose a paint/hardener combination accordingly.

5. Coat On Coat

It’s very important to clearly understand the method of usage regarding AC lacquer. Determine where the product can be used as a single-product sealer/topcoat or whether it requires a separate base and topcoat product.

6. Volume Solids

Volume solid percentage tends to vary significantly between suppliers – this does effect usage a lot therefore it is essential to check the volume solid % relative to your requirements in order to select the most cost-effective option.

7. Stackability

This is often an important consideration, as it effects your workflow and overall productivity. Check the product Technical Data Sheet to find the advised stacking time, and determine how that will work for you to produce the best possible results.

8. Polishing

The length of time before polishing can vary between systems. The majority of AC systems will advise around 72 hours before polishing, but do check this before selecting your preferred system.

9. PPE

In relation to Point 3 above, PPE is important to comply with health and safety legislation for the usage of coating systems. Check the requirements and ensure the correct PPE is being used.

Related Article: '5 Things You Should Know About The Transition From Solvent To Waterborne Coatings'

10. Low Odour

Some AC coatings can have strong odours making usage unpleasant. However certain ranges are classified as low odour to help mitigate the strong solvent smell – this is obviously particularly important if you are applying the product on a client’s site.

11. Universal

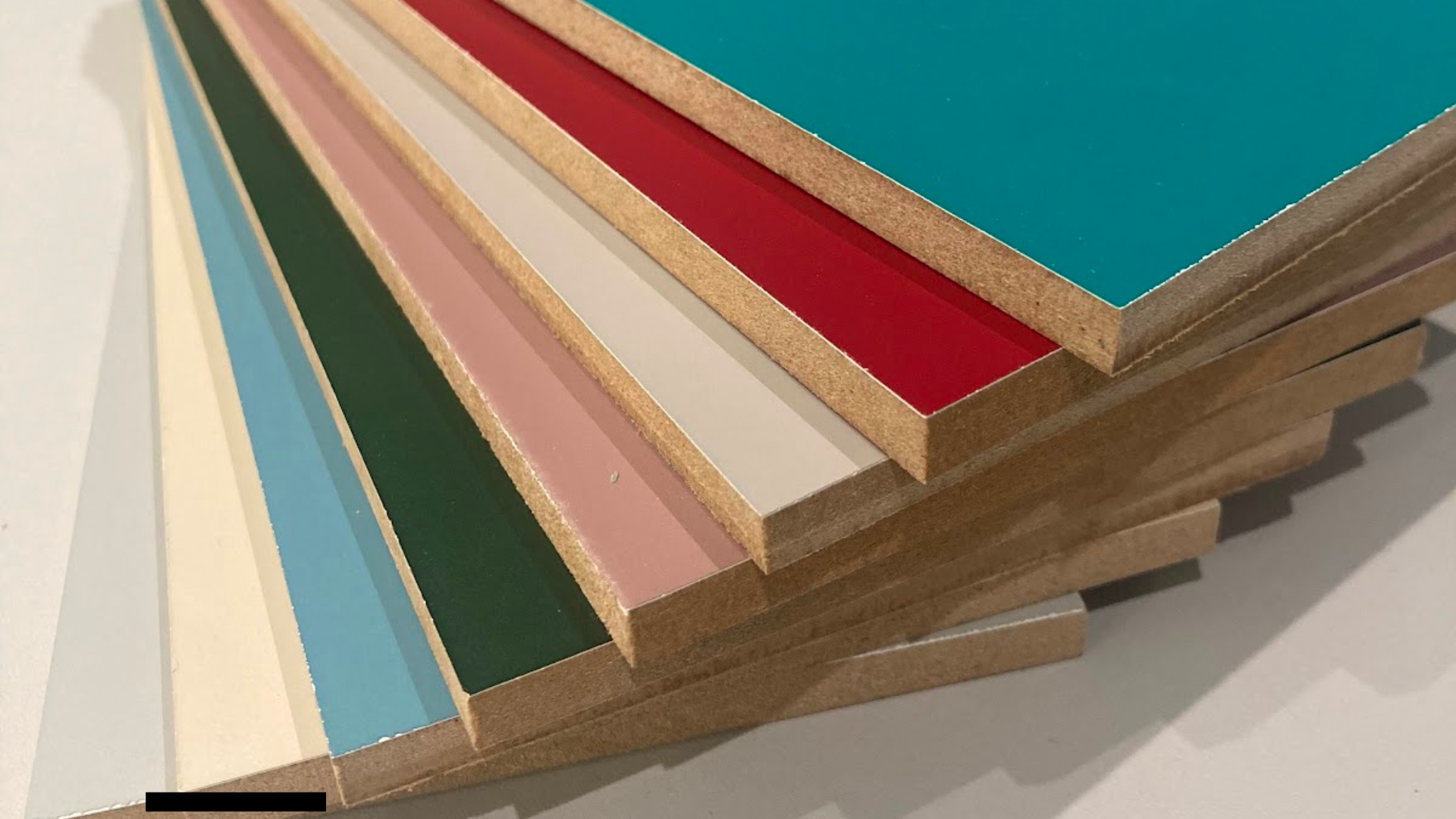

Explore the potential for universal systems. Some AC ranges will can be overcoated with a water-based topcoat allowing for a more user/environmentally-friendly hybrid system, whilst other products will react if used this way.

12. Sheen Levels

Some products have a

limited gloss range - ensure your preferred

coating option is available in a full range, to avoid being potentially unable to meet a your clients’ requirements.

13. Activator

For ease of use, choose a system that uses the same hardener and same mixing ratio across primer, pigmented topcoats and lacquer. This keeps the system simple and reduces risk of any errors when mixing.

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

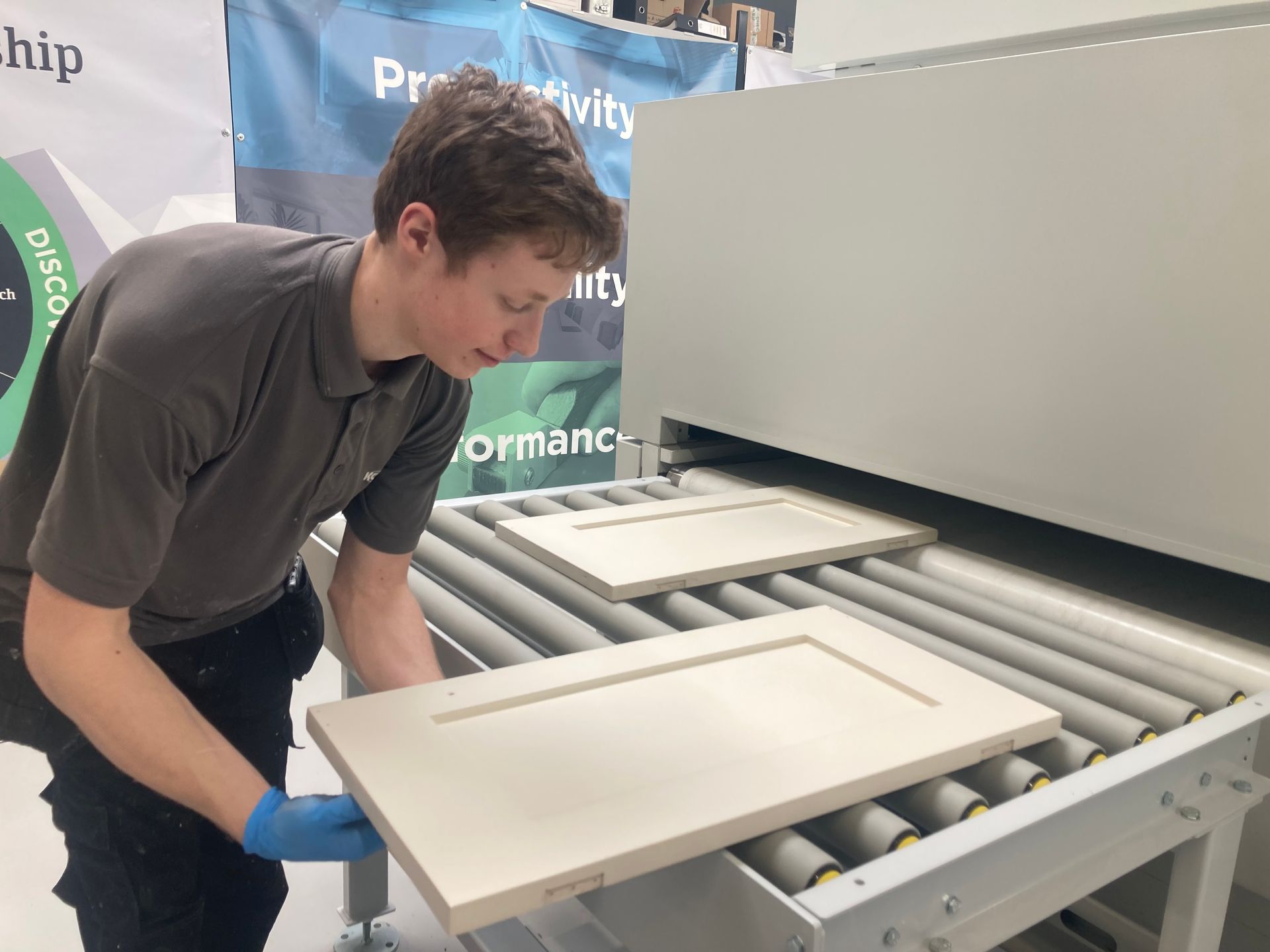

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.