Case Study: Symphony Group

Case Study: Symphony Group

Issues with the switch to water-based products with poor standards and batch-to-batch consistency.

In an attempt to move away from solvent-based coatings, Symphony Group found a water-based coatings supplier yet faced issues with the finish quality and batch-to-batch colour consistency. In understanding Symphony Group's existing processes, Kortec reviewed areas whereby essential improvement can be made to reach their short-term and long-term goals.

Analysis

Assessment of all aspects of the coating process

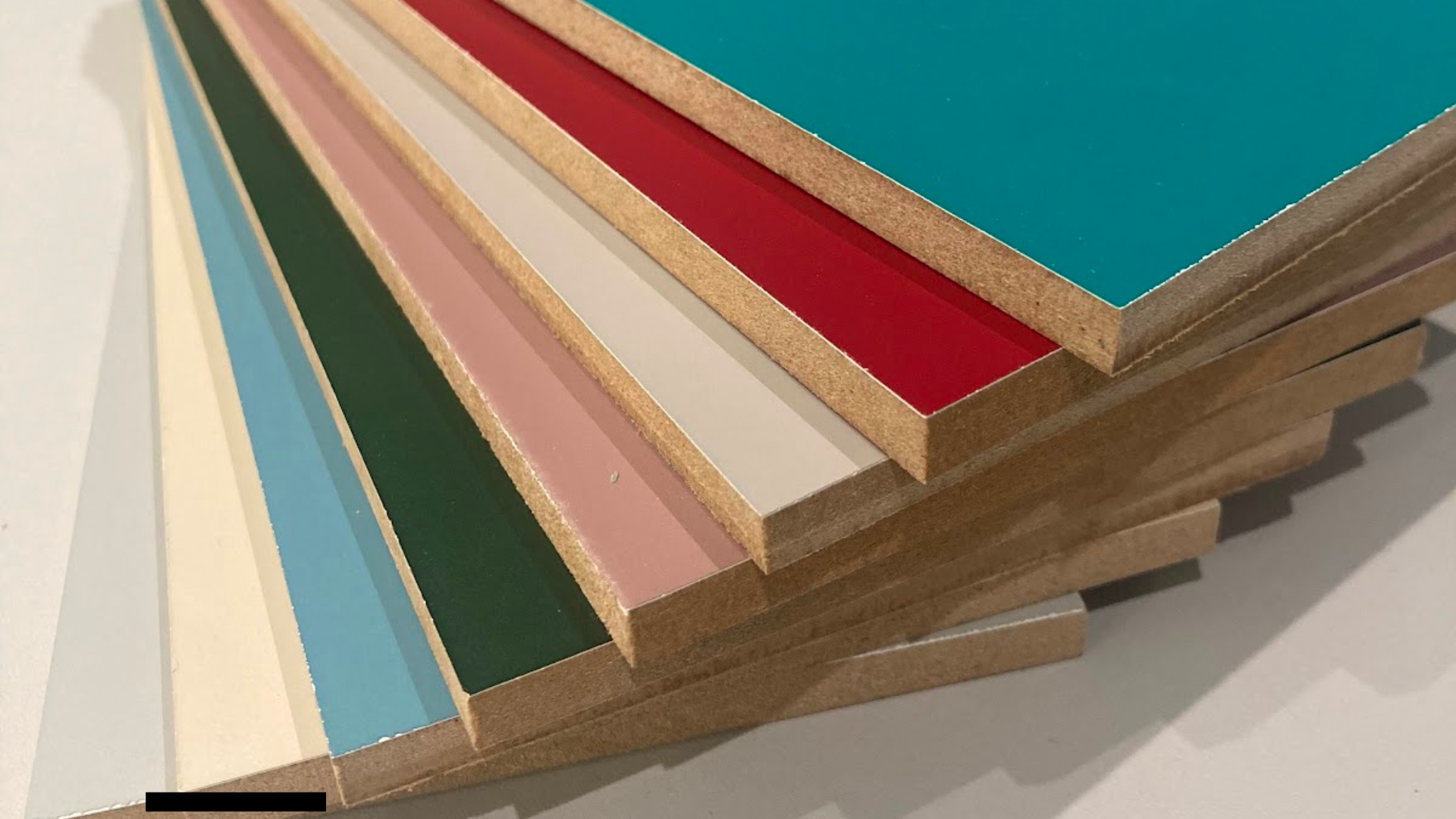

When we first started working with Symphony Group they had a range of approximately 20 standard colours which required high standards of colour consistency from batch-to-batch production. All their procedures and quality control were in place but as they made the switch from solvent-based to water-based coatings (with a previous supplier), they experienced finish quality and colour consistency issues that needed to be resolved.

Implementation

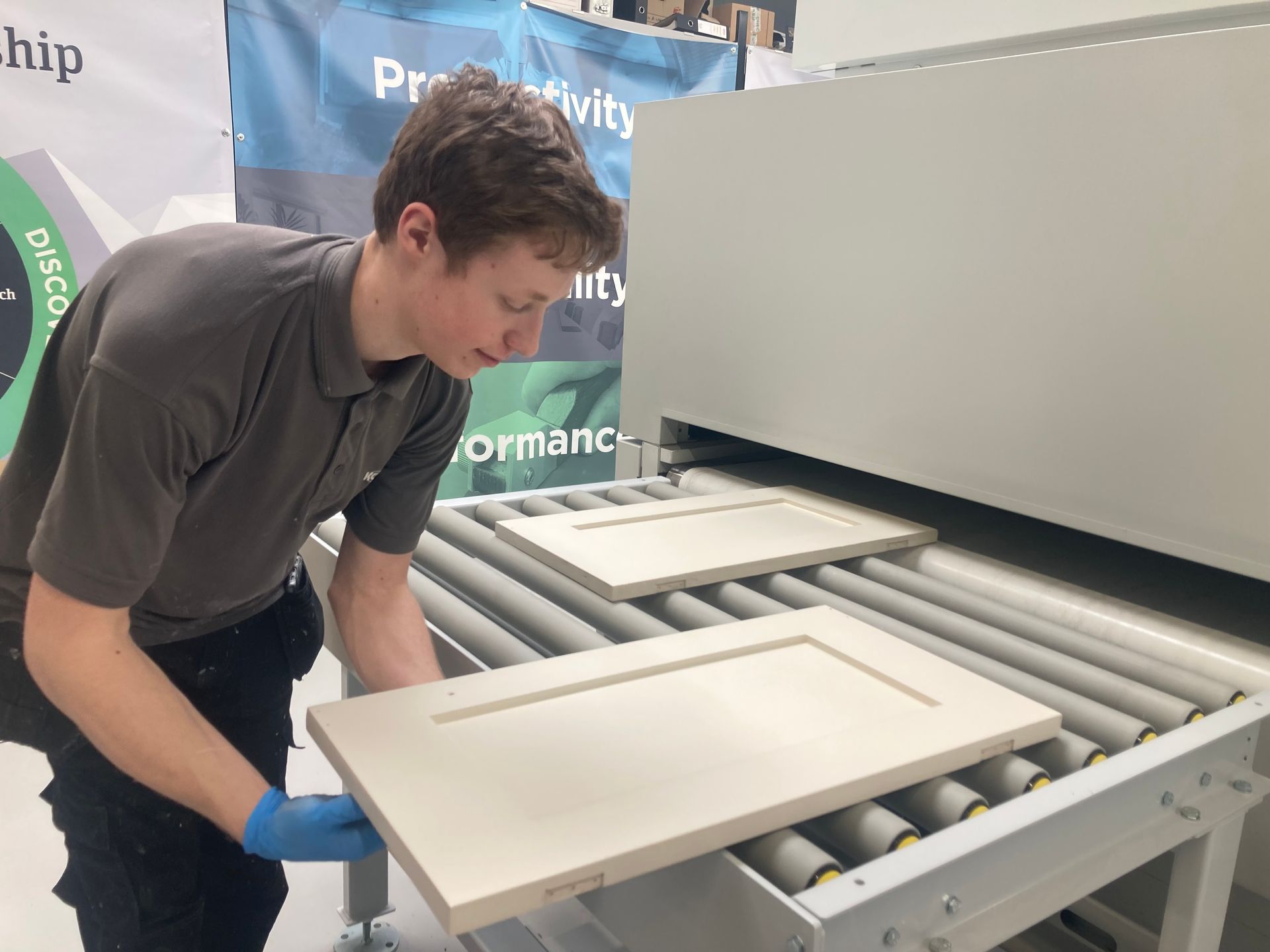

Optimised machinery to improve finish quality

Our great level of experience dealing with water-based products enabled us to work closely alongside Symphony Group to find a solution that would provide them with a quality finish and colour consistency. The team optimised the spray/cure machine settings to improve the finish quality and implemented strict quality controls to ensure accurate/consistent colour matching going forward.

Related Article: 'Save £1000’s, How Much Does A Water-Based Coatings System Cost?'

Ongoing Client Benefits

Increase in output and reduction in staffing costs

Since the implementation, Symphony Group has achieved a 50% increase in production output whilst reducing spray shop staff by 30%. Additionally, their colour match rejects rate is down to less than 0.5% which is a huge achievement in comparison to previous batch-to-batch inconsistencies. Kortec continues working closely with Symphony Group and has recently received FIRA Gold Accreditation.

Hear From Symphony Group...

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.