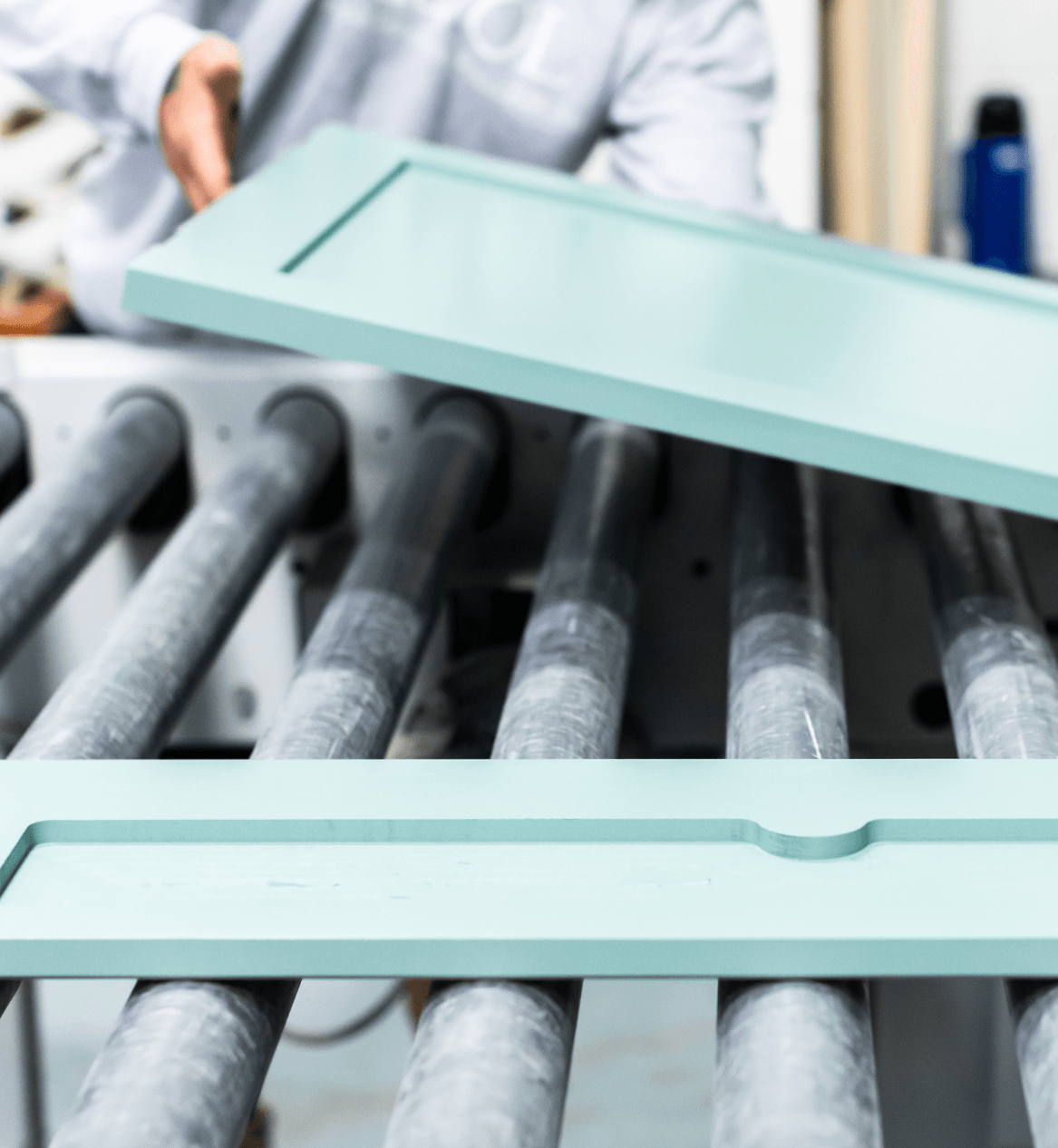

Minimise System Application Times With Wood Coating Solutions

Make the switch to a reliable wood coating solution that creates the perfect finish time after time, ideal for internal & external joinery, retail & hospitality manufacturers.

"Kortec have consistently delivered when we needed it most, bringing new products to market and assisting with the development of our product offer." - Symphony Group

Peace Of Mind With Our Halo Promise - Exceptional Communication & Fast

Peace Of Mind With Our Halo Promise - Exceptional Communication & Fast Delivery

Wood Coatings Supplier Wood Paints Supplier UK

High-Quality, Consistent & Faultless Wood Coating & Wood Paint Solutions

Exceed expectations with an extensive range of wood coatings and wood paints that have minimal production & drying times, an optimised finish, an increased service life and edges towards sustainability.

We Help Businesses

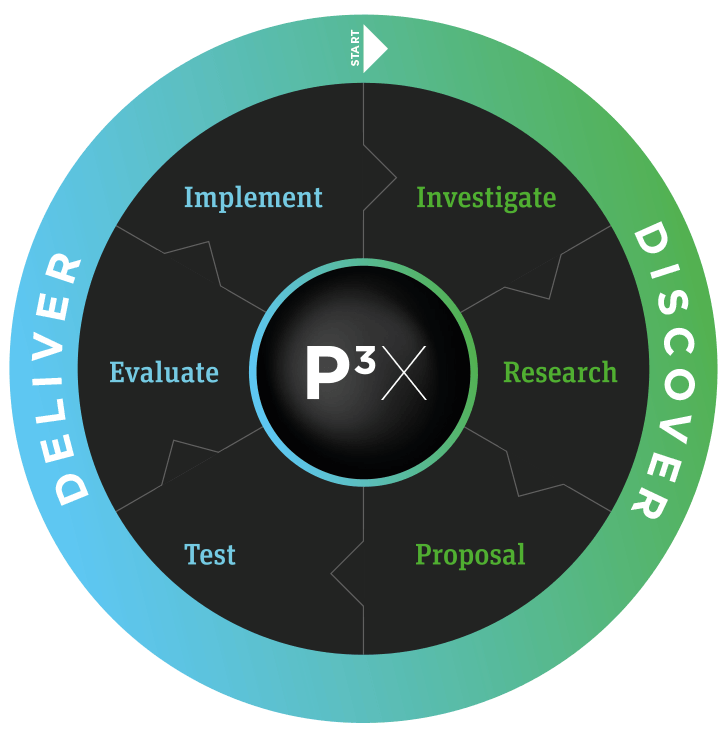

Optimising Businesses With Our Proven P3X Processes

Increased Productivity

Maximise production efficiency by reviewing and implementing changes for your entire process, from substrate preparation to packaging/delivery.

Improved Profitability

Helping you achieve previously unrealised efficiencies and gains by fully understanding your product journey and making appropriate changes.

Enhanced Performance

Developing expert in-house processes that will positively impact the short-term and long-term benefits for both yourself and your clients.

Increased Productivity

Maximise production efficiency by reviewing and implementing changes for your entire process, from substrate preparation to packaging/delivery.

Improved Profitability

Helping you achieve previously unrealised efficiencies and gains by fully understanding your product journey and making appropriate changes.

Enhanced Performance

Developing expert in-house processes that will positively impact the short-term and long-term benefits for both yourself and your clients.

Tried & Tested Wood Paint Solutions UK

Helping Industries Develop Smarter Ways Of Working

Using The World's Best Brands

Our Trustworthy Coating Brands Offer Durability & Flexibility

At Kortec we promise to only use brands that we can whole heartedly trust, typically their product and value align with that of our own. See our most popular below...

-

Sayerlack

Learn moreItalian multinational company developing innovative wood solutions.

-

Varlaq

Learn moreFlexibility of choice to create the finish you want, at a price you can afford.

-

Fire Retardants

Learn moreCombining the best quality with constant innovation and creativity.

Combined With Unbeatable Performance

Become A Business That Works Smarter With The Help Of Kortec

"The customer service is amiable, yet professional, and the level of communication is exactly what is required to keep our workshop running without delays." - deVOL Kitchens

Wood Coating FAQ's

-

1. How do I compare the costs of wood coating systems?

It is important to consider many other factors besides just the price per litre/kg.

Does the product require an activator/hardener or cross-linker? How many coats are required to achieve the necessary durability and/or finish quality. What will it cost to dispose of any waste? What application/drying/curing facilities are required?

Make sure you assess the cost of the whole coating process, not just the direct material price.

Refer to articles: What Coating Type Is The Cheapest For Internal Wood Finishing? and Save £1000’s, How Much Does A Water-Based Coatings System Cost?

-

2. Which wood coatings give the best performance?

Performance is best to be evaluated according to industry standards that quantify specific durability values such as BS6250/BS6222 for internal coatings, or CATAS for external joinery protection.

Application properties also affect “production” performance so please refer to What Coating Type Gives The Best Overall Finish & Durability?

-

3. What are the common wood coating problems?

Coating a natural or absorbent/fibrous substrate such as timber or engineered wood substrates such as MDF or plywood presents multiple challenges.

Check out whether some coatings may react with oils/tanins in your specific substrate. Test to see which coating raises the least fibres.

Balance your drying processes to avoid bubbling/fizzing on the surface.

More factors are mentioned in 4 Things You Must Be Aware Of When Using An AC Coatings System and 4 Most Common Problems With 2-Pack Polyurethane Paint & Lacquer and 5 Most Common Concerns With A Water-Based Coating System.

-

4. How easy is it to move to water-based coatings?

The timber coating industry is making a big shift to using water-based coatings. The majority of external joinery coatings have been water-based for quite a few years, but the internal furniture market is still going through this migration.

There are a number of factors to consider but it doesn’t need to feel daunting as Kortec have taken many of our clients through this process. Some of these are covered here 5 Things You Should Know About The Transition From Solvent To Water-Based Coatings and a basic spray equipment changeover process can be found here WB to SB Instructions.

-

5. What is your typical lead time?

We typically deliver goods ordered in 1-2 days. However, for clients that require our optimum level of colour matching accuracy within Delta E 0.3, this can require 3-4 days to ensure the colour has completely stabilised within these parameters.

-

1. How do I compare the costs of wood coating systems?

It is important to consider many other factors besides just the price per litre/kg.

Does the product require an activator/hardener or cross-linker? How many coats are required to achieve the necessary durability and/or finish quality. What will it cost to dispose of any waste? What application/drying/curing facilities are required?

Make sure you assess the cost of the whole coating process, not just the direct material price.

Refer to articles: What Coating Type Is The Cheapest For Internal Wood Finishing? and Save £1000’s, How Much Does A Water-Based Coatings System Cost?

-

2. Which wood coatings give the best performance?

Performance is best to be evaluated according to industry standards that quantify specific durability values such as BS6250/BS6222 for internal coatings, or CATAS for external joinery protection.

Application properties also affect “production” performance so please refer to What Coating Type Gives The Best Overall Finish & Durability?

-

3. What are the common wood coating problems?

Coating a natural or absorbent/fibrous substrate such as timber or engineered wood substrates such as MDF or plywood presents multiple challenges.

Check out whether some coatings may react with oils/tanins in your specific substrate. Test to see which coating raises the least fibres.

Balance your drying processes to avoid bubbling/fizzing on the surface.

More factors are mentioned in 4 Things You Must Be Aware Of When Using An AC Coatings System and 4 Most Common Problems With 2-Pack Polyurethane Paint & Lacquer and 5 Most Common Concerns With A Water-Based Coating System.

-

4. How easy is it to move to water-based coatings?

The timber coating industry is making a big shift to using water-based coatings. The majority of external joinery coatings have been water-based for quite a few years, but the internal furniture market is still going through this migration.

There are a number of factors to consider but it doesn’t need to feel daunting as Kortec have taken many of our clients through this process. Some of these are covered here 5 Things You Should Know About The Transition From Solvent To Water-Based Coatings and a basic spray equipment changeover process can be found here WB to SB Instructions.

-

5. What is your typical lead time?

We typically deliver goods ordered in 1-2 days. However, for clients that require our optimum level of colour matching accuracy within Delta E 0.3, this can require 3-4 days to ensure the colour has completely stabilised within these parameters.

"Kortec have supplied us in our furniture manufacturing operation for 5 years. We use Kortec because we can order any quantity on a next day delivery and have found this service to be reliable. The reps are friendly and can not do enough for you."

Jonathan Smith - Rorla

"Kortec provide a service that is second to none. Reliable deliveries, quality paint at affordable prices. Never any stock issues."

Simon Cooper - Fowler & Gilbert Ltd

"We can always rely on Kortec to provide a highly efficient standard of service - Always helpful when colour matching samples and provide a good technical support"

Louise Sheppard - Unity Doors Ltd

"Kortec provide a service that is second to none. Reliable deliveries, quality paint at affordable prices. Never any stock issues."

Simon Cooper - Fowler & Gilbert Ltd

"We can always rely on Kortec to provide a highly efficient standard of service - Always helpful when colour matching samples and provide a good technical support"

Louise Sheppard - Unity Doors Ltd

"Kortec have supplied us in our furniture manufacturing operation for 5 years. We use Kortec because we can order any quantity on a next day delivery and have found this service to be reliable. The reps are friendly and can not do enough for you."

Jonathan Smith - Rorla

Why Trust Kortec For Your Coating?

-

Watch Case Study

Button

Success Story: Symphony Group

In an attempt to move away from solvent-based coatings, Symphony Group found a water-based coatings supplier, yet faced issues with finish quality & batch-to-batch colour consistency. Kortec assessed the process and implemented methods to make goals achievable... Read More

Highly Responsive

Our team will provide a response to any email or enquiry within just 30 minutes.

Fast Quoting

Order confirmations or pricing requests will be provided within 60 minutes.

Prompt Delivery

Two-day delivery as standard, with next-day delivery available on request.

Great Communication

No need to chase for progress updates, our team will keep you informed.

Clear Product Data

Concise, effective product guides are provided with everything we supply.

Highly Responsive

Our team will provide a response to any email or enquiry within just 30 minutes.

Fast Quoting

Order confirmations or pricing requests will be provided within 60 minutes.

Prompt Delivery

Two-day delivery as standard, with next-day delivery available on request.

Great Communication

No need to chase for progress updates, our team will keep you informed.

Clear Product Data

Concise, effective product guides are provided with everything we supply.

How We Do It

A Perpetual Cycle Of Continuous Evaluation & Improvement

From implementing a detailed discovery and research phase to gain a complete understanding of your product and process — through to rigorous testing, evaluation and guided implementation— our process is designed to optimise productivity, profitability, and performance.

We call this P3X.

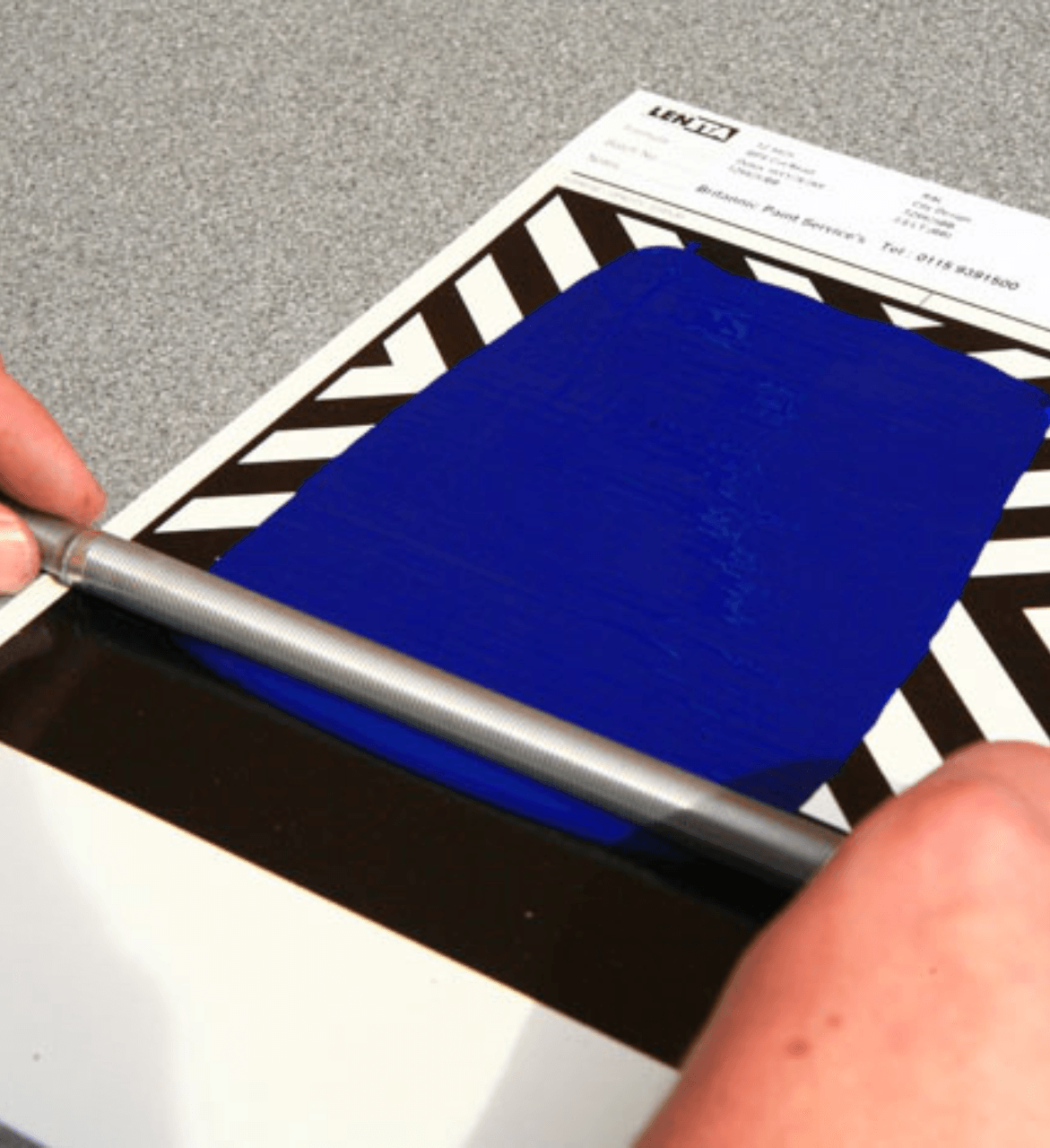

Kolorteq TM

The Process Lays

The Foundation & We Provide The Flawless Finish

The KolorteqTM process enables accurate and consistent reproduction of standard and bespoke colours. This is vital for batch-to-batch consistency optimising client satisfaction and minimising remedial works.

Every colour/batch produced is checked against the respective control sample. These strict procedures have enabled us to achieve a client colour batch rejection rate of less than 1 in 2500.

In House Testing

Meticulous Material Checks Conducted By Experienced Lab Technicians

At Kortec, we have 4 lab technicians with a combined total of over 40 years of expert experience in the coatings production industry, they are certified in the Farnsworth-Munsell 100 Hue Test.

For consistency and high-quality finish purposes, each batch of base material and pigments are checked prior to use to assess any variations in strength and our tinting formulations are adjusted to compensate prior to production.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.