Case Study: Charles Yorke

Case Study: Charles Yorke

From dealing with adhesion & durability struggles to zero issues for 365 days and counting...

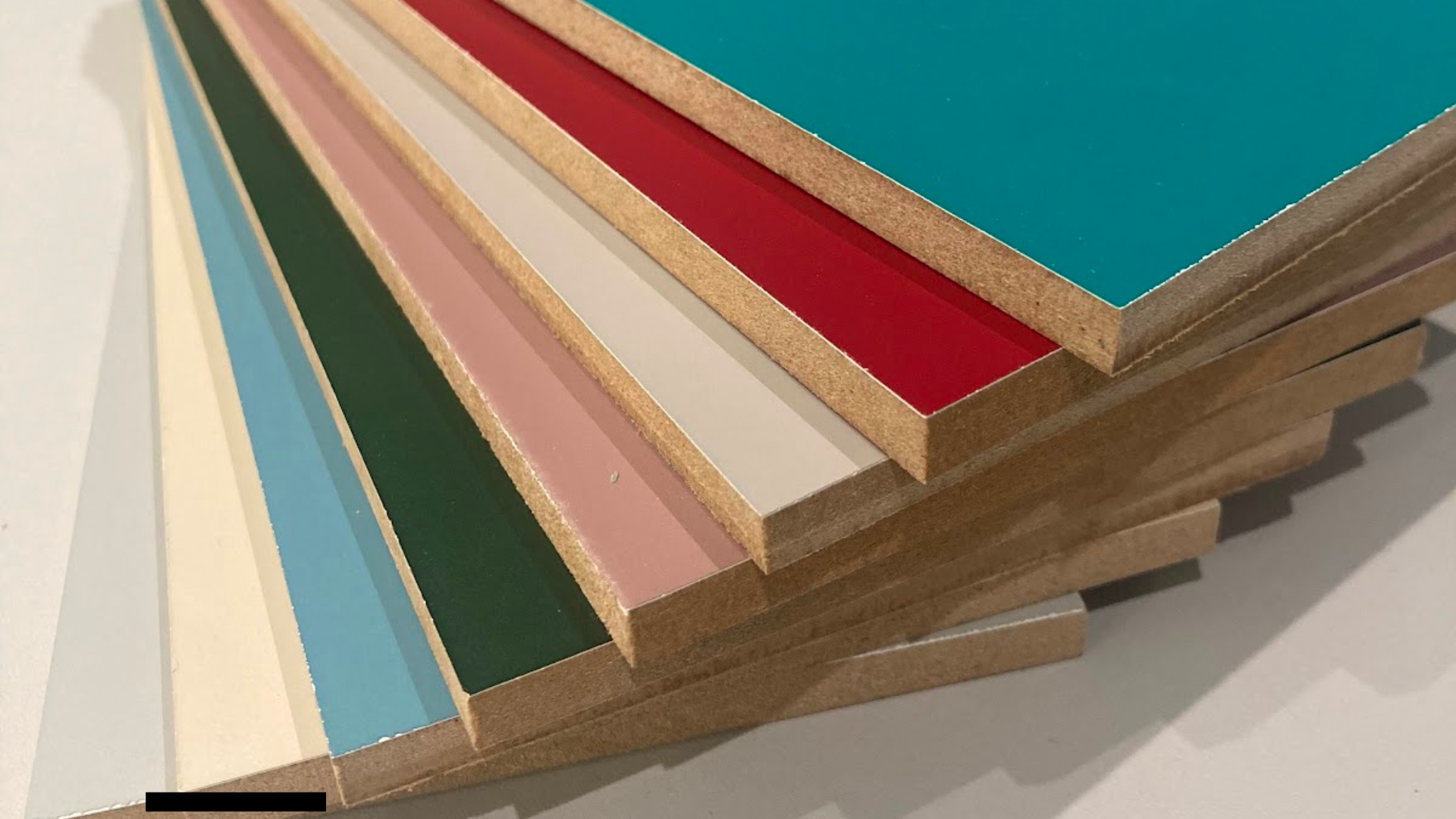

Charles Yorke specialises in producing bespoke handcrafted kitchen, bedroom & bathroom furniture. Before working with Kortec, they were using a combination of Autoline and hand spray and were struggling with adhesion issues and the durability of their coatings.

Analysis

Assessment of all aspects of the coating process

During the analysis stage conducted by Kortec, it was apparent that Charles Yorke was dealing with adhesion issues. There were concerns regarding the long-term durability of their bespoke handcrafted home furniture as a result of their current water-based paint system.

As a leading supplier of high-quality furniture, it was essential that these issues were resolved quickly and efficiently with colour-matching accuracy to ensure they could continue production of high-quality furniture.

Implementation

All standard colours matched via KolorteqTM programme

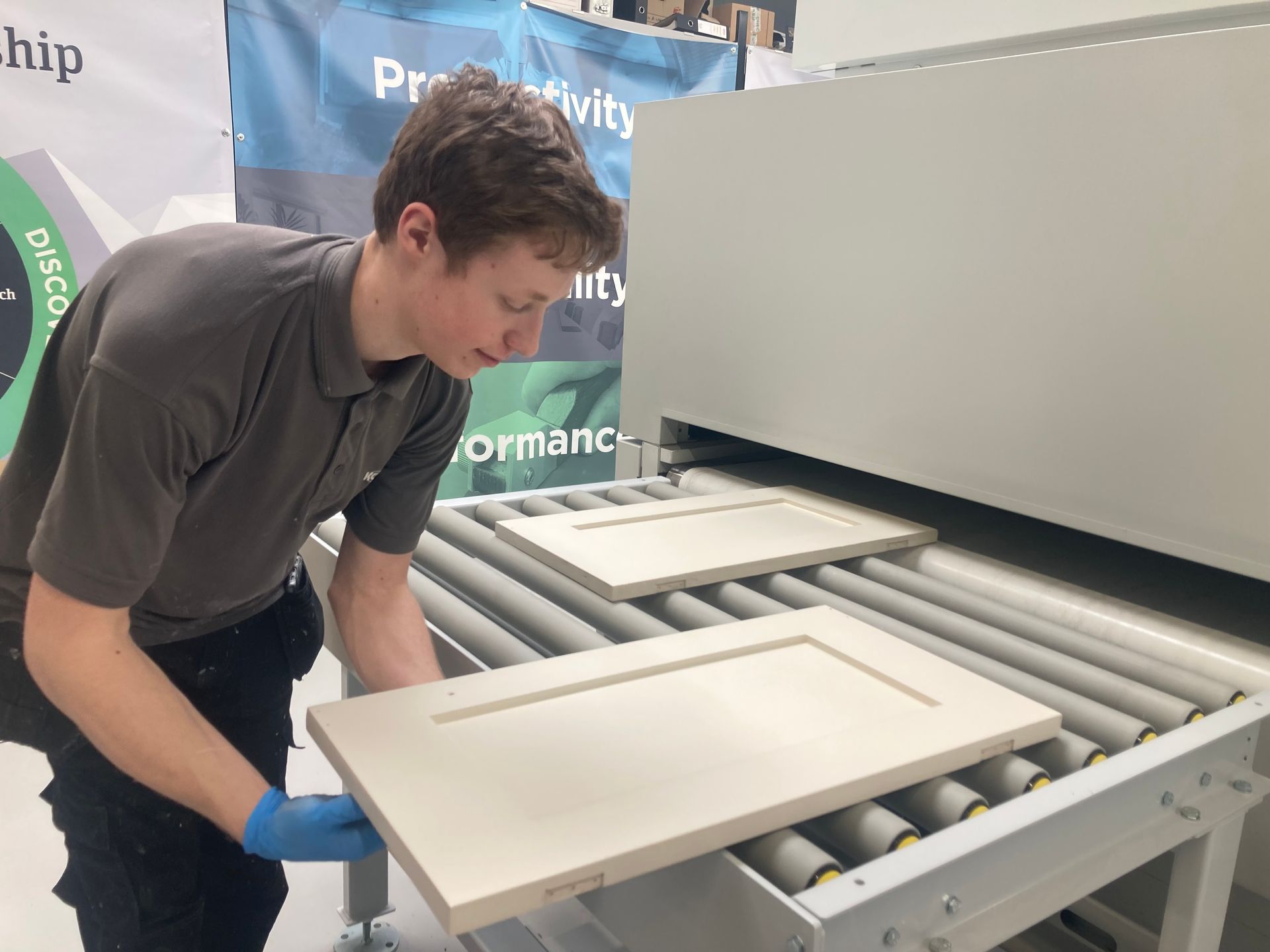

After reviewing the situation and developing possible solutions, Kortec provided Charles Yorke with a superior single-pack water-based topcoat. In doing so, this made the process far easier allowing the staff at Charles Yorke to touch up on-site. In addition, Kortec provided Charles Yorke with a compatible primer to ensure optimum results were obtained.

Related Article: '5 Things You Should Know About The Transition From Solvent To Waterborne Coatings'

Ongoing Client Benefits

Structured assessment on a weekly basis

Since the implementation advised by Kortec, Charles Yorke has been using the single-pack water-based topcoat for over 1 year, in this time they have not experienced any adhesion or durability issues. Furthermore, they have reduced their primer usage by over 25% as equivalent build/finish quality is achieved with a film weight of 125g/m² instead of 175g/m².

"Working alongside Kortec for the past two years has been a very smooth process, They have fantastic products and customer service, which allows our paint shop to be efficient and to produce the highest quality."

- Simon Daker, Operations Manager

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.