P3X: What Can You Gain and How?

P3X: What Can You Gain and How?

P3X is what we see as the key elements we provide to you: Productivity, Profitability and Performance.

Kortec’s goal has always been to deliver optimum solutions for your particular case, and an Efficient Coating System depends on meeting your needs in every one of these three key areas.

A one-size-fits-all approach can never deliver that, and we also see delivering P3X as a continuous cycle; we may deliver a system that ticks all the boxes in 2023 and by 2025 technological advances and circumstantial changes might mean an entirely different system is appropriate.

So what might P3X mean for you? As you’d expect, it could mean almost anything but below we’ve tried to give a picture of what it could include.

Productivity

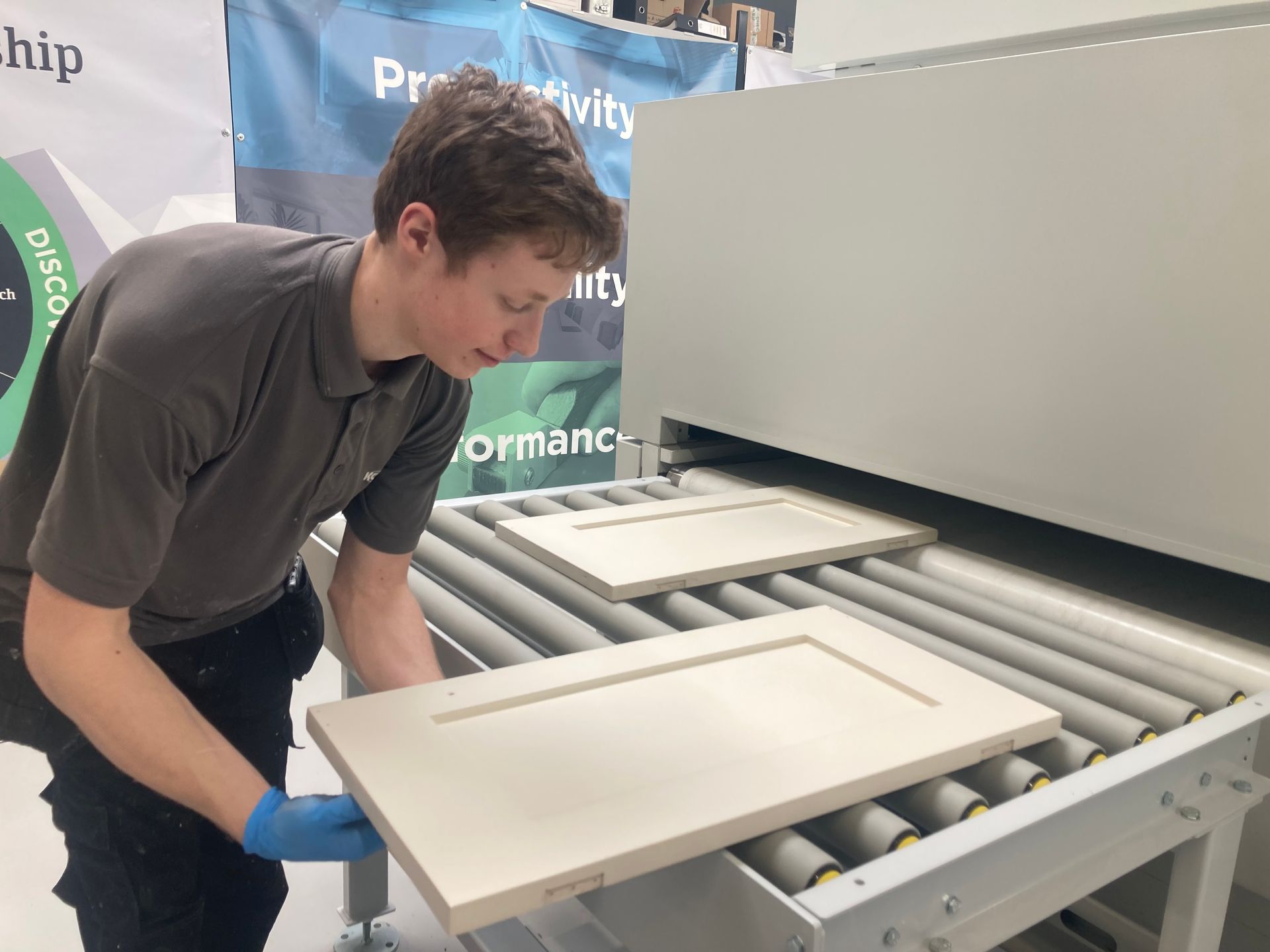

This is almost always the stated top priority – almost any company is looking to improve productivity where possible! Modern manufacturing processes have improved every part of the process, but often painting is the hardest to systemise and gets left to the last. Due to this and the inherent drying times, the paint element of the manufacturing process is typically a bottleneck for our clients.

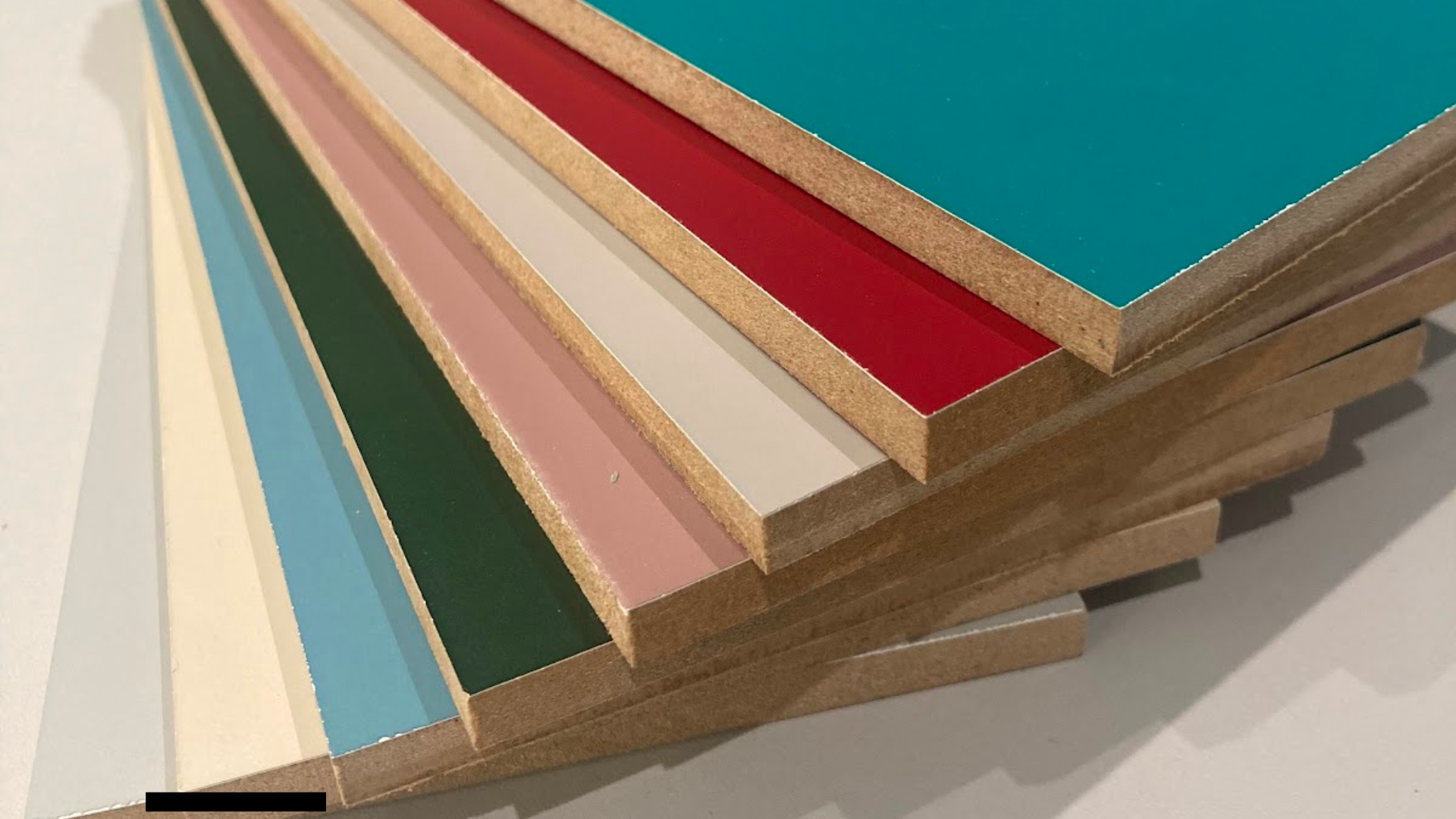

Addressing that always starts with a thorough Investigation phase - identifying what you do and how you do it. Then we analyse what the bottlenecks are and how they might be resolved; it could be as outside-the-box as recommending a higher-quality mdf to enable coating in 3 coats of paint instead of 4, or as simple as switching to a high-opacity primer/finish to achieve full opacity in one coat. The potential gains are massive - 25% productivity increase is common and it can be much higher.

This is why we rely on high-quality products delivered by technically expert partnerships - the extra cost of a high-performance product is far less than the resulting productivity improvements can generate in profit, when used correctly in the right situation.

Readers Also Liked: 'Top Obstacles to Consistent Colour'

Profitability

Profitability increases are normally delivered by productivity improvements enabling reduced material costs per items, or increased output while controlling costs.

Typically this is achieved with a combination of three methods;

1. reducing the coating cost per unit (not necessarily the coating price per litre!)

2. minimising the labour cost per unit (possibly preparation or application, or both)

3. increasing handling/production speed, allowing greater throughput and therefore increased potential profit generation per day for the same fixed cost amount

Good products can be applied in thinner or a lower number of coats, can tolerate more efficient preparation methods and can be dried a lot faster than the norm - as long as you know the limits of what is possible and the techniques to get the best results.

It’s about changing the conversation from paint cost per litre, to labour + materials + workshop time per unit – maximising your output while minimising costs to increase your productivity.

Performance

Performance can be a buzzword but we know it’s critical for our clients, as their paint finish is the first thing their client sees on their product.

The level required is very dependent on the needs and aims of the client, and typically falls under one of three types:

1. There is a current performance issue that we need to resolve, such as poor adhesion, insufficient durability or inconsistent results

2. The client requires a performance upgrade, normally either due to a new specification from one of their clients or to uplift the quality of their offering for competitive advantage

3. Performance just needs to be maintained at the current standard, because Productivity and Profitability are their priority goals - often in this situation we can offer a Performance upgrade anyway as a side benefit of achieving the other goals!

The key is always to clearly define what the goal is, then thoroughly test our solution to prove that it achieves the criteria consistently.

Summary

We believe that our P3X approach is key to our clients’ success – for too long the paint industry as a whole has stuck by antiquated technologies and an outdated “here’s the same thing for a better price” approach. The Kortec team firmly believe that “better is possible” and are continually developing new ranges, new technologies and growing our expertise in delivering them.

To see where a P3X journey might take you get in touch today – we’re always glad to discuss what might be possible for you!

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.