PreCat vs Water-based Coatings – Which Should I Use?

PreCat vs Water-based Coatings – Which Should I Use?

Precat and water-based paints actually have several characteristics in common – making a choice between them depends on several factors, including your specific project requirements, health and safety, application method, and drying conditions.

What would Precat Coatings give you?

1. Durability: Precat offers good resistance to scratches, chemicals, and moisture. It provides a protective coating that can withstand daily use and is often chosen for exhibition stands, tabletops and skirting to name a few examples.

2. Finish Quality: Precat will provide a flat, smooth finish which should remain this way for a minimum of 12 months, depending on whether it is in a high traffic environment or not.

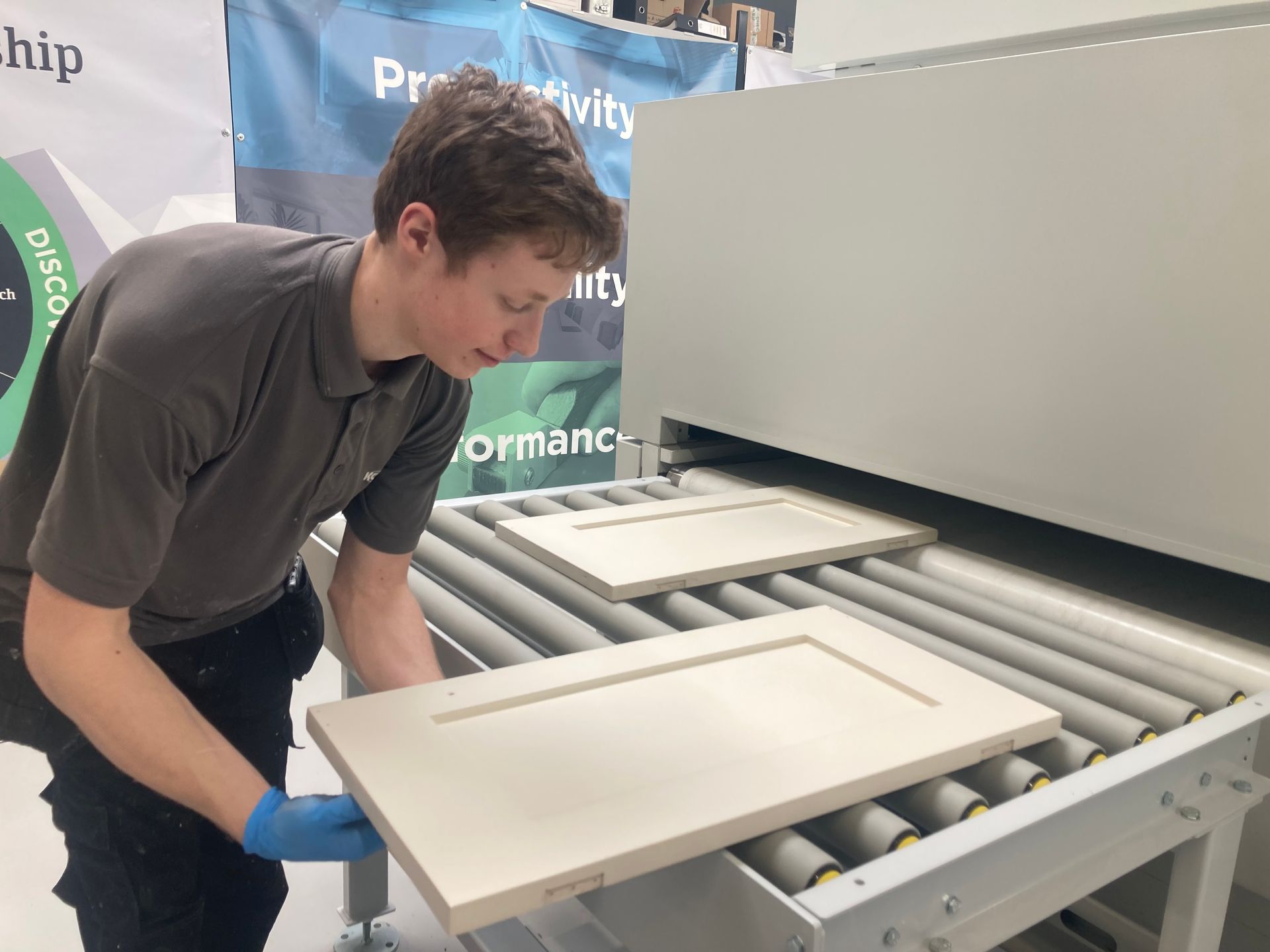

3. Application: Spraying is the only real viable option here, due to how fast the material flashes off. This makes brushing or rolling the product extremely difficult.

4. Drying Time: Precat will dry extremely fast due to its self-curing properties. This allows for

fast production cycles, in terms of both flipping a product for spraying and wrapping products once finished and complete.

Readers Also Liked: 'Liquid vs Solid Paint Content – Why Does It Matter?'

What would Water-based Coatings offer instead?

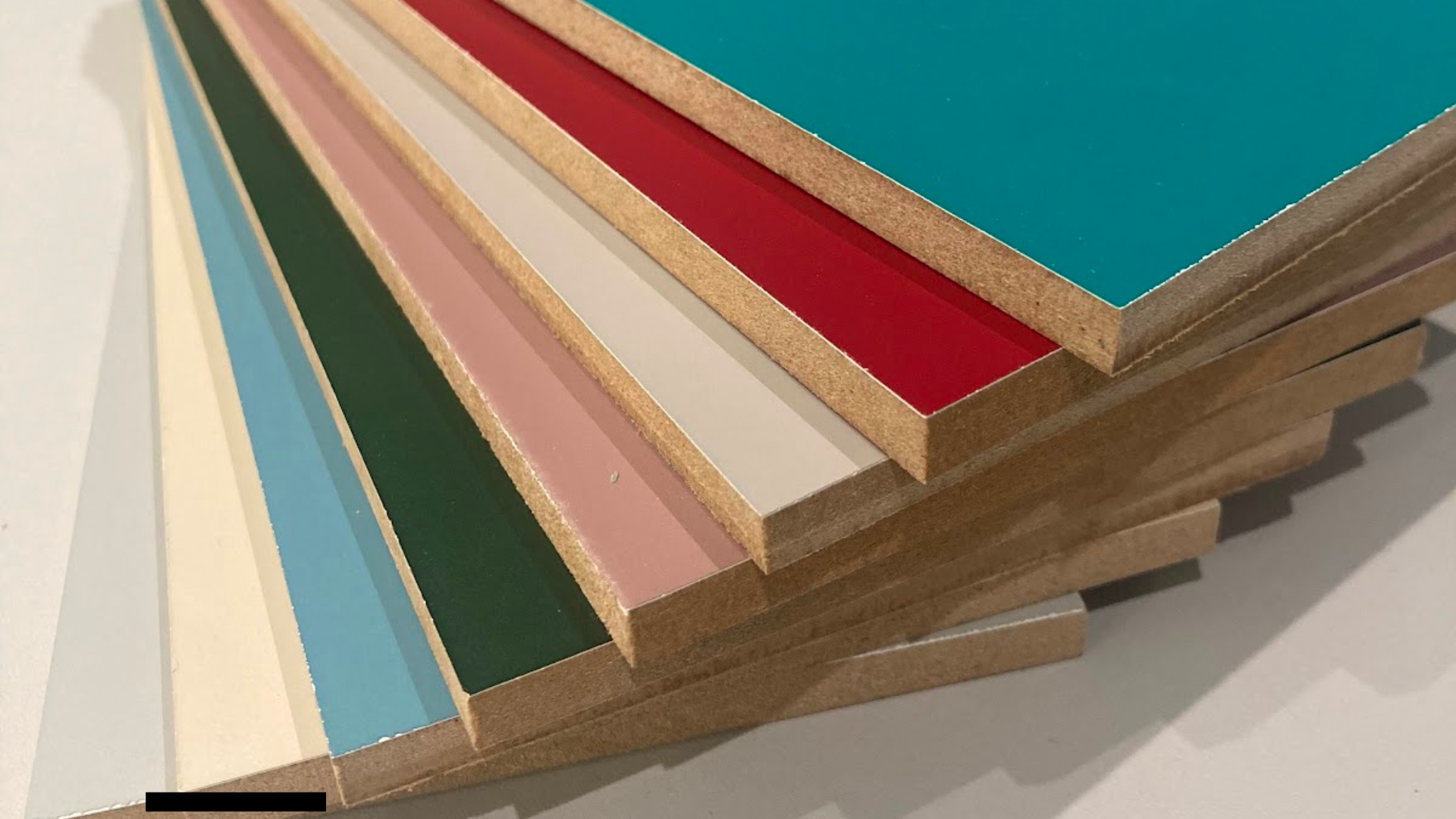

1. Environmental Considerations: water-based paints contain far less volatile organic compounds (VOCs) compared to solvent-based finishes like precat. It is significantly more environmentally friendly and is therefore a preferred option for those concerned about air quality and emissions.

2. Reduction in Solvents: Water can be used to thin water-based coatings, as well as cleaning equipment after use. This eliminates the need for any solvent thinners or solvent cleaner, with their high VOC content, flammability risks and disposal difficulties.

3. Odour and Health Concerns: these coatings are relatively low-odour compared to solvent-based finishes, making them more suitable for indoor projects or those with limited extraction. They are generally safer to use and have lower health risks than the precat equivalents.

4. Marketing: Water-based coatings can provide your business with some key USPs that can be used for advertising and marketing to your clients. Using low odour, eco-friendly paints is something that clients are increasingly looking for as part of their decision-making process.

5. Finish & Application: assuming that a quality product is used correctly, the durability and appearance of the finish achieved should be at least as good as the precat options. It can also be brushed or rolled, which can be useful to achieve a traditional “hand-finished” look or in situations requiring remedial works.

Ultimately, the choice between precat and water-based coatings depends on your specific needs and preferences, but the factors we’ve covered above are worth considering in order to make an informed decision.

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.