Case Study: Thorpes Joinery

Case Study: Thorpes Joinery

“We decided it was time to move from 2-pack Polyurethane to 1-pack Water-based coatings, and we did this starting with the lacquer”

Analysis

Assessing all aspects of the coating process

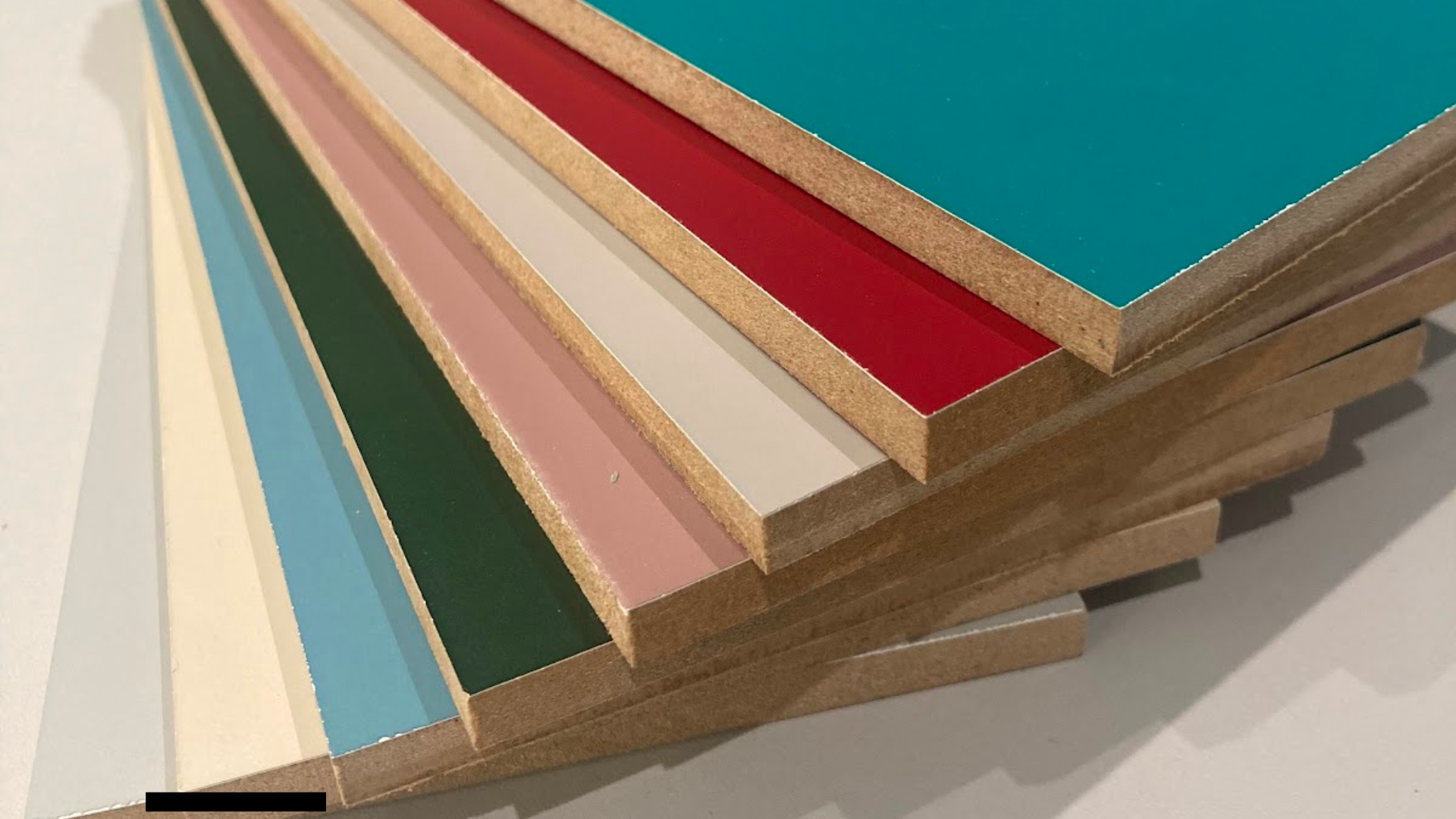

Thorpes Joinery had been using 2-pack polyurethane coatings for the best part of ten years. When moving to their new state-of-the-art, purpose-built factory in Market Harborough, they took the decision to start a transitional journey to water-based materials.

Implementation

Testing our water-based coatings to replace the existing durability standard

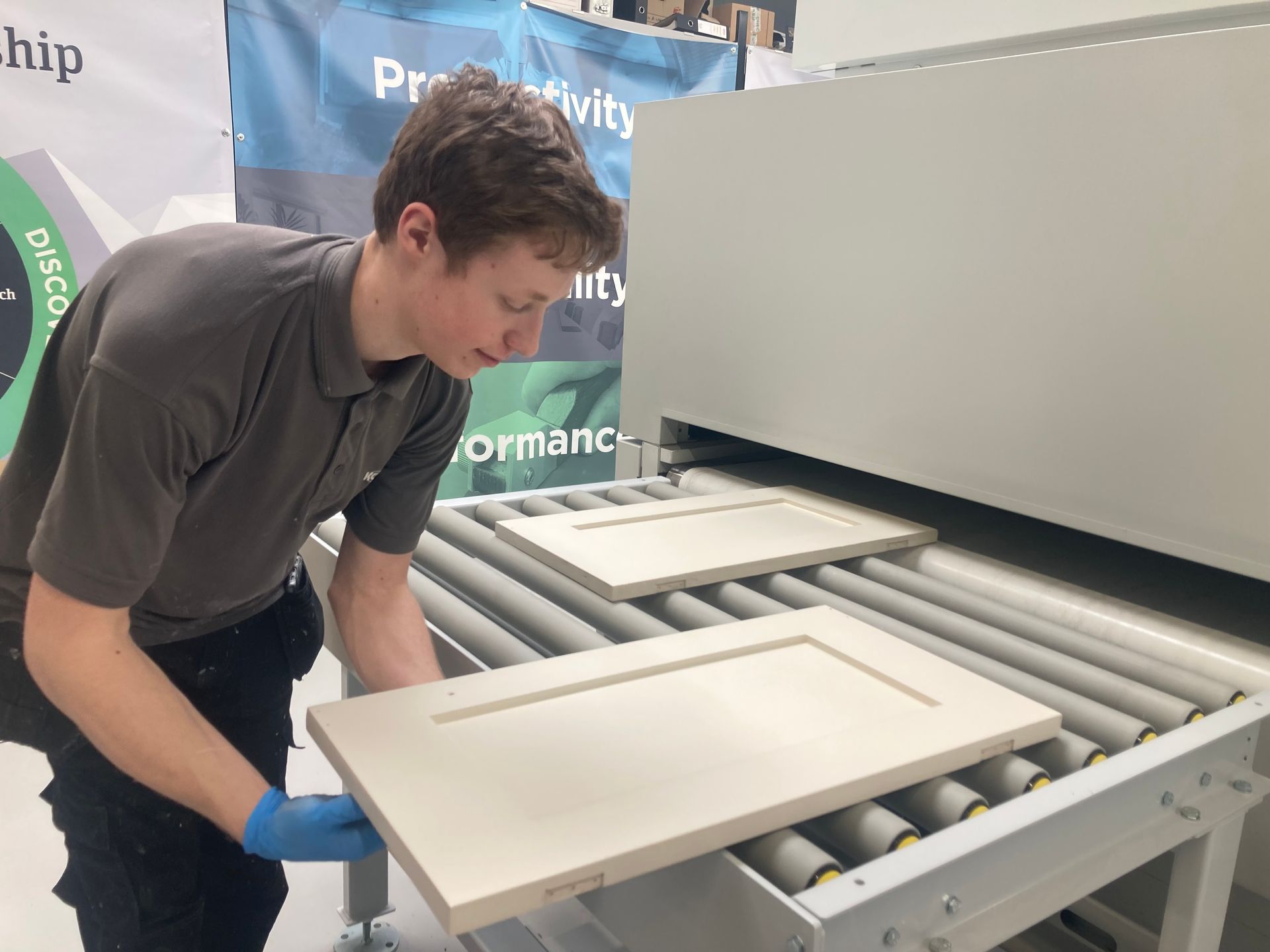

As a starting point, they wanted to look at replacing their clear lacquer as the first step. This would allow for them to start their analysis of how the water-based coatings would spray, the flow properties, drying and overall finish and durability. Due to their new facilities, they already had an excellent spray booth that allowed for both heat and air movement, providing the optimum drying conditions. The first job was completed for a large coffee retailer, covering hundreds of table tops. The combination of their own in-house testing and our certificate of independent FIRA testing gave the confidence and assurances required for the job.

Ongoing Benefits

After a short trial period, the client moved over full to water-based coatings

Our client continued to use water-based clear lacquer and very quickly grew to depend on the added benefits of single pack technology meaning no pot life, no wastage and a very fast turnaround between coats. This resulted in them also moving over the primer and pigmented topcoats, after building up their confidence so quickly on the lacquer.

The reduction in mixed waste, cleaning time and overall insurance costs is significant, and in addition multiple new contracts were won due to ticking the boxes of BREEAM compliancy.

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.